Commercial applications of this metal shaping process often involve complex geometries with straight sides and radii. In such a case, the term stamping is used in order to distinguish between the deep drawing (radial tension-tangential compression) and stretch-and-bend (along the straight sides) components. Deep drawing is always accompanied by other forming techniques within the press. These other forming methods include:

- Beading: Material is displaced to create a larger, or smaller, diameter ring of material beyond the original body diameter of a part, often used to create O-ring seats.

- Bottom Piercing: A round or shaped portion of metal is cut from the drawn part.

Bulging: In the bulging process a portion of the part’s diameter is forced to protrude from the surrounding geometry. - Coining: Material is displaced to form specific shapes in the part. Typically coining should not exceed a depth of 30% of the material thickness.

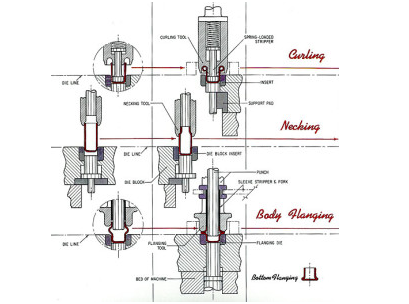

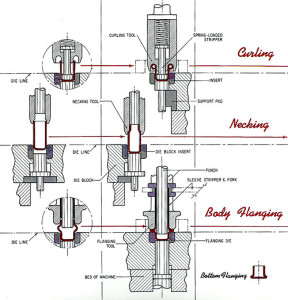

- Curling: Metal is rolled under a curling die to create a rolled edge.

- Extruding: After a pilot hole is pierced, a larger diameter punch is pushed through, causing the metal to expand and grow in length.

- Ironing / Wall Thinning: Ironing is a process to reduce the wall thickness of parts. Typically ironing should not exceed a depth of 30% of the material thickness.

- Necking: A portion of the part is reduced in diameter to less than the major diameter.

- Notching: A notch is cut into the open end of the part. This notch can be round, square, or shaped.

- Rib Forming: Rib forming involves creating an inward or outward protruding rib during the drawing process.

- Side Piercing: Holes are pierced in the side wall of the drawn part. The holes may be round or shaped according to specifications.

- Stamping / Marking: This process is typically used to put identification on a part, such as a part number or supplier identification.

- Threading: Using a wheel and arbor, threads are formed into a part. In this way threaded parts can be produced within the stamping press.

- Trimming: In the Trimming process, excess metal that is necessary to draw the part is cut away from the finished part.

Operations

- Bending – the material is deformed or bent along a straight line.

- Flanging – the material is bent along a curved line.

- Embossing – the material is stretched into a shallow depression. Used primarily for adding decorative patterns. See also Repoussé and chasing.

- Blanking – a piece is cut out of a sheet of the material, usually to make a blank for further processing.

- Coining – a pattern is compressed or squeezed into the material. Traditionally used to make coins.

- Drawing – the surface area of a blank is stretched into an alternate shape via controlled material flow. See also deep drawing.

- Stretching – the surface area of a blank is increased by tension, with no inward movement of the blank edge. Often used to make smooth auto body parts.

- Ironing – the material is squeezed and reduced in thickness along a vertical wall. Used for beverage cans and ammunition cartridge cases.

- Reducing/Necking – used to gradually reduce the diameter of the open end of a vessel or tube.

- Curling – deforming material into a tubular profile. Door hinges are a common example.

- Hemming – folding an edge over onto itself to add thickness. The edges of automobile doors are usually hemmed.