Capacity

- Single run, progressive die, transfer presses

- Low to high volume

- 50 to 5,000,000 pieces

Equipment

- Hydraulic, mechanical, pneumatic and transfer

- Up to 300 tons

Finishing Processes

- Drawn corner radii as small as .002″ (0.05 mm)

- Degreasing, deburring, heat treating, and passivating

- Anodizing, polishing, painting, powder coating, bead blasting and plating

- Piercing, extruding, bulging, coining, tapping and machining

- Resistance spot welding, TIG welding, laser welding and brazing to MIL specifications

- Assembly of components and brackets to deep drawn enclosures

- PEM®, stud and standoff insertions

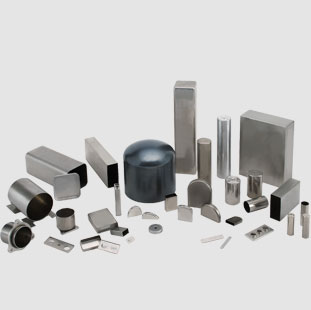

Materials

- Cold rolled steel, stainless steel, aluminum, copper, brass, Monel®, titanium, Hastelloy®, Kovar®, nickel, Inconel®, Mumetal®, tantalum and others

Sizes

- 1/16″ to 18″ (1.6 mm to 457 mm) diameter

- Lengths up to 18″

- Material thicknesses .002″ to .250″ (0.05 mm to 6.35 mm)

Precision / Tolerances

- ± .0005″(0.013 mm)

- Drawn corner radii as small as .002″ (0.05 mm)