Aerospace / Defense

Parts made from hard-to-draw materials such as stainless steels, Inconel® , titanium, and Hastelloy® meet the industry’s stringent requirements

Value-added services such as manufacture of brackets and standoffs, assembly, welding, plating, and non-destructive testing reduce the multiple tiers in your supply chain

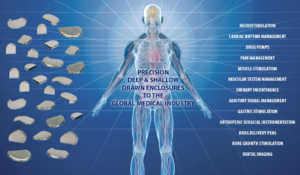

Medical

National Manufacturing has many decades of World Class Quality experience working in the medical device industry. We work with many of the industry’s leading medical device manufacturers.

Deep drawn and shallow drawn cases are used in implantable medical devices such as:

- Pacemakers

- Defibrillators

- Batteries

- Capacitors

- Drug Delivery

- Pain Management

- Surgical Devices

Electronics

Materials – All drawable materials such as CRS, stainless steel, nickel, Mumetal®, tantalum, Monel®, aluminum, copper, brass, Inconel®, titanium, Kovar®, and Hastelloy®

Value added services – surface coating, soldering, brazing, finishing, stud, standoff insertions and bracket assemblies